Introduction

Electric discharge machining (EDM) is process that

uses electrical sparks to machine metals into desired shape. EDM is usually

used for hard metals or those that would be difficult to machine with

conventional techniques. Using Computer Numerical Control (CNC) technology, EDM

process is made accurate and programming method can be simplified for effective

production. This course focuses on EDM die sinker process where electrode is

used to create cavity on the workpiece. Participants will have opportunity to

learn the basics of CNC EDM die sinker process including operation method and

programming.

Target Group

This course is suitable for persons from machining

related industries for example machinist or machine operators who want to learn

how to operate a CNC EDM die sinker machine. This course is also suitable for

experienced personnel who wish to refresh their knowledge in EDM.

Prerequisites

This course is a basic-level course. Prior knowledge

of CNC is not necessary to enroll in this course.

Objectives

Upon completion of the course, the participants should

be able to:

Use proper and safe procedure

for operating a CNC EDM machine

Write simple programs for EDM

Determine appropriate machining conditions based on work piece or product requirement

Determine proper tools for machining

Test run program on an actual CNC EDM

Write simple programs for EDM

Determine appropriate machining conditions based on work piece or product requirement

Determine proper tools for machining

Test run program on an actual CNC EDM

Content

The Basics

a.

Machining preparation &

setup

b.

Method of clamping &

confirming parallelism

c.

Operations during machining

d.

Configuration of portable

operation panel

e.

Manual operation

Operating using the main panel

a.

Basic functions

b.

Address keys & numeric

symbols

c.

Machining status display areas

Model plan menus

a.

Machining model plan

b.

Positioning model plan

c.

Measuring model plan

d.

Auxiliary model plan

Programming

a.

Program structure and format

b.

Using the Edit screen

c.

Programming input example

Machining

a.

Electrode reduction

b.

Automatic machining operation

c.

Machining method

d.

Jump pattern and setting

e.

Model monitor screen

f.

Selection and use of model data

g.

Model plan applications

h.

G & M code explanation /

examples

Training Method

Training will be delivered through short lecture, demo

and practical lesson. The emphasis for this course is on hands on practical

sessions.

Schedule

Day 1

08:30 a.m. Registration

09:00 a.m. Introduction

/ preparation & set-up for machining

10:30 a.m. Break

11:00 a.m. Operation

with portable operation panel

01:00 p.m. Lunch

02:15 p.m. Model

plan menus and explanations

05:00 p.m. End

of day 1.

Day 2

08:30 a.m. Program

structure & standard format

10:30 a.m. Break

11:00 a.m. Automatic

machining operation

01:00 p.m.

Lunch

02:15 p.m. Model

plan applications / cutting

05:00 p.m. End

of day 2

Day 3

08:30 a.m. G

and M codes explanation and examples / project

10:30 a.m. Break

11:00 a.m. Cutting

/ Project

01:00 p.m. Lunch

02:15 p.m. Question

& Answer

05:00 p.m. Closing

ceremony

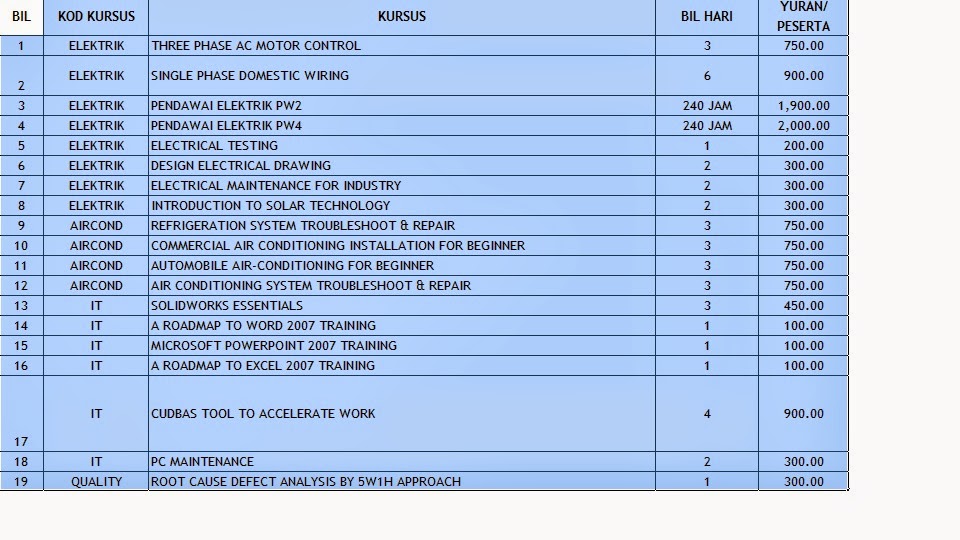

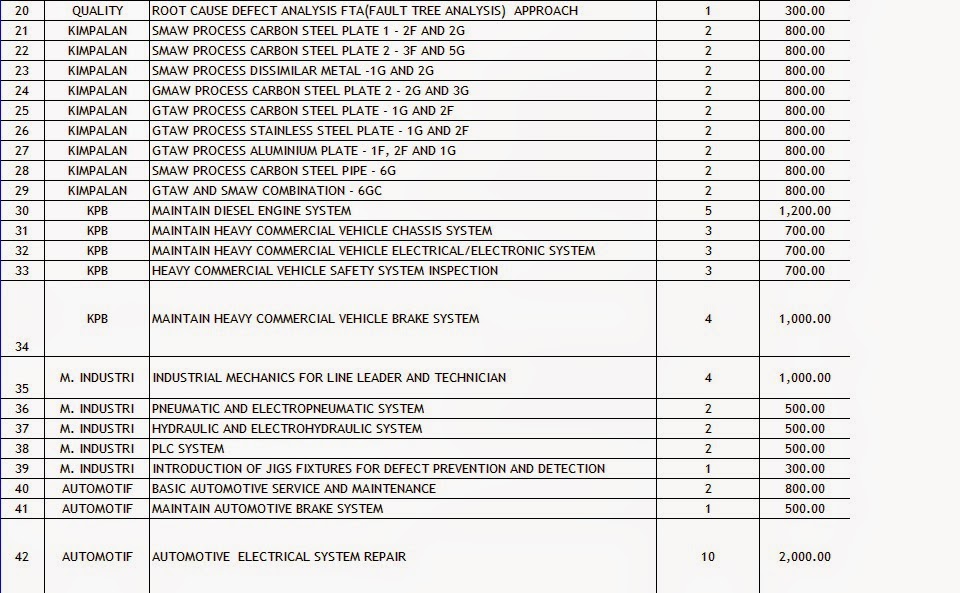

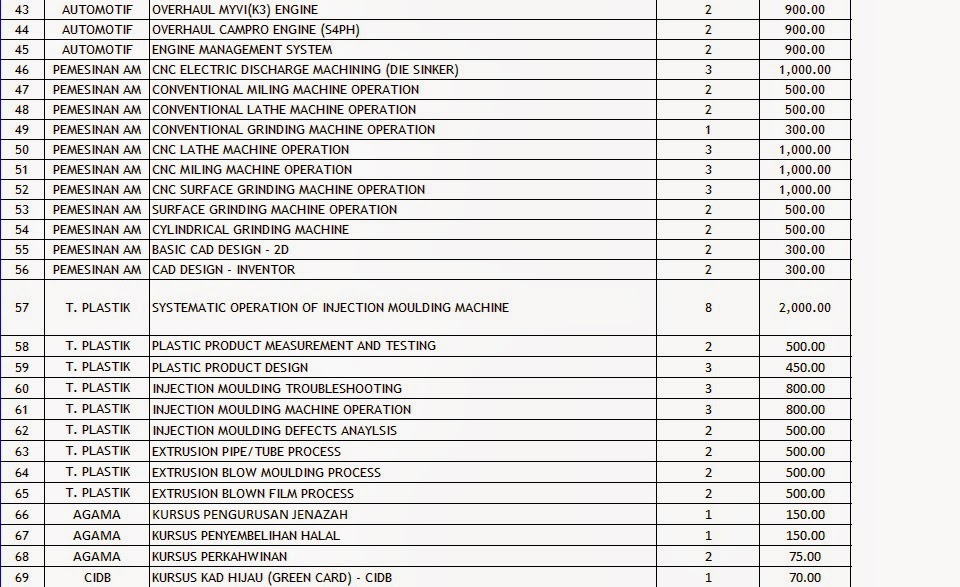

Fees

Companies sending their employees to this course may apply for reimbursement

from Human Resource Development Fund under the SBL scheme.